- HardNess

-

Metallurgical Equipment

- Metallographic sample cutting machine series

- Metallurgical mounted machine series

- Grinding machine

- Metallographic grinding prototype, polished machine, pre-mill series

- Polishing machine

- Metallographic polishing machine, grinding and polishing machine series

- Microscope

- Metallographic analysis system

- Electrolytic polishing corrosion tester

- Sample blower

- End quenching equipment

- Metallurgical Material

Contact:Miss zhang

Phone:021-51083791

Fax:021-51083792

Mobile:18930516192

Email:teshi@teshish.com

THBS-3000XP-AZF Automatic Brinell hardness testerasq

Name:

THBS-3000MDXP-AZF Fully automatic Brinell hardness tester

Advantages:

Automatic Brinell hardness based primarily << GB / T 231.1 (ISO6506-1) >> Brinell hardness test, used to measure the Brinell hardness of metals and some non-metallic materials.

The hardness of high precision, high degree of automation for measurements of high precision large or high-end users.

- Automatic turret samples automatically rise

- Automatic test force is applied

- Automatic indentation fight

- Automatic Sample Decreasing

- Automatic turret for easy operation

- Automatic tested surface position Focus

- Automatic indentation diameter measurement

- GB / ASTM hardness automatic conversion;

- Unqualified value automatic alarm;

- Automatically customized inspection reports generated

Application areas:

Metallurgy ,metrology , Building materials, research institutes ,hardening shops, stainless steel, automotive, railway, energy, steel, aviation , roller plants, tube rolling mills, foundries,

Workpieces application:

Non-hardened steel, cast iron, non-ferrous metals, alloys bearing ,plates, sheets, motor blocks, rails, rings, bars, tires, wheels, castings

Main Parameters :

| Brinell Scale |

HBW2.5/62.5, HBW2.5/187.5,HBW5/125, HBW5/750 HBW10/100、HBW10/1500 HBW10/3000HBW10/250 HBW10/500 HBW10/1000 |

| Testing Force |

62.5 (612.9), 100 (980.7), 125 (1226), 187.5 (1839), 250 (2452), 500 (4903), 750 (7355), 1000 (9807), 1500 (14710), 3000 (29420) Kgf(N) |

| Accuracy of Test Force |

0.1%.acuracy Better than normal Brinell hardness tester 1% (when test force ≥ 1000Kgf) |

| Max Height of Specimen | 320mm |

| Dwelling time | 5~60s |

| Hardness testing Range | 8~650HBW |

| Standard conformed to | GB/T231.2 , JJG150 |

| Distance of Indenter to outer wall | 200mm |

| Main unit weight | About 90kg |

| Power source | AC220±5%,50~60Hz |

| Dimension (mm) | 550*210*750mm |

| Samples rise | Automatic / manual |

| Fight indentation | Automatic |

| Samples decline | Automatic / manual |

| Image Focus | Automatic / manual |

| Turret | Auto / Manual |

| Camera (pixels) | 1.3M |

| Indentation measurement | Manual / automatic |

| Hardness value displayed | Automatic |

| Hardness Conversion | GB / Auto |

| Unqualified value alarm | Automatic |

| Statistical analysis of hardness | Yes |

| Hardness testing database query | Yes |

| Cstomized inspection reports | Automatically generated |

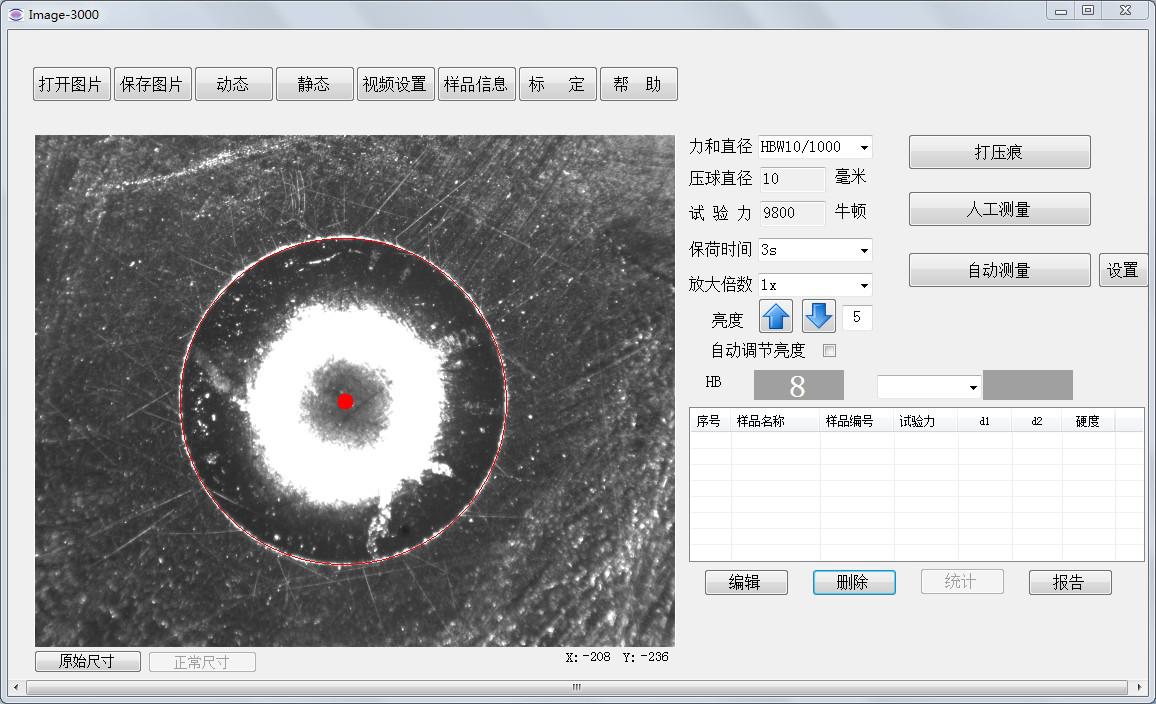

Software Interface display:

The specific configuration of THBS-3000MDXP-AZF

| No. | Quantity | Content discription |

| 1 | 1pc | Digital Brinell hardness tester |

| 1-1 | 3pcs. | Large, medium, V-test sets (one each) |

| 1-2 | 3pcs. | 2.5,5,10mm diameter carbide ball indenter |

| 1-3 | 3pcs. | Standard test blocks (high, medium and low one) |

| 1-4 | 1pc | Objective (interior) |

| 1-5 | 1pc | Power line |

| 1-6 | 1pc | Operation Manual |

| 2 | 1set. | Automatic control, measurement and image processing system |

| 2-1 | 1pc |

Industrial controllers (Lenovo's commercial computer) |

| 2-2 | 1pc | 1.3-megapixel digital camera industry |

| 2-3 | 1pc | Optics and C-mount adapter |

| 2-4 | 1set. | Automatic control, measurement and image processing system |