Product Classification

- HardNess

-

Metallurgical Equipment

- Metallographic sample cutting machine series

- Metallurgical mounted machine series

- Grinding machine

- Metallographic grinding prototype, polished machine, pre-mill series

- Polishing machine

- Metallographic polishing machine, grinding and polishing machine series

- Microscope

- Metallographic analysis system

- Electrolytic polishing corrosion tester

- Sample blower

- End quenching equipment

- Metallurgical Material

Contact Info

Contact:Miss zhang

Phone:021-51083791

Fax:021-51083792

Mobile:18930516192

Email:teshi@teshish.com

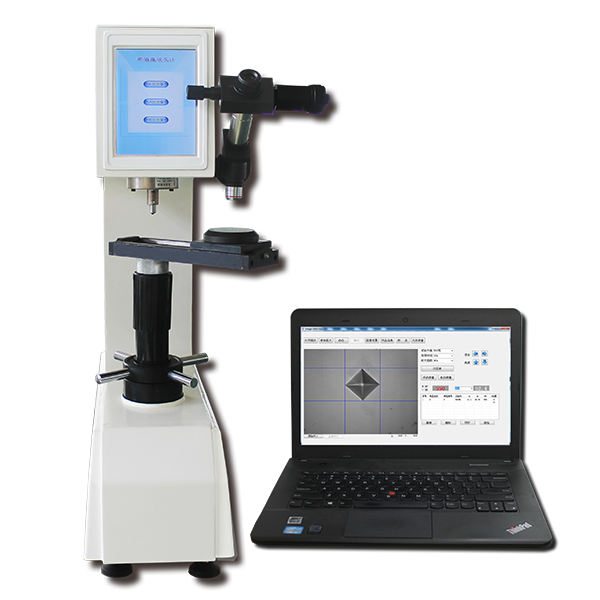

THUS-187.5 Universal Hardness Tester

THUS-187.5 Universal Hardness Tester

Product Introduction:

- THUS-187.5 Universal Hardness Tester can be used to measure the hardness of Brinell, Rockwell, Superficial Rockwell and Vickers;

- Closed-loop sensor loading control system with high precision and stability;

- Automatic loading and unloading;

- Automatic pre-loading when measure the hardness of Rockwell;

- Automatic measurements for the Rockwell, Brinell and Vickers values;

- The software provides the functions of hardness conversion, upper and lower limits settings and hardness rectification;

- RS232 port interface can be connected with the printer or computer;

- Permanent storage of testing results for database view;

- Automatic generation of custom-made inspection report.

Technical Specifications

| Loading Method | Sensor loading, closed-loop control Driving method:high-precision ball screw shaft Force measuring method:high precision pressure sensor |

| Hardness scales | Brinell、Vickers、Rockwell、Superficial Rockwell、HVT, HBT |

| Testing load | 1-187.5kg |

| Measuring range of Brinell | HB2.5/:6.25、15.625、31.25、62.5、187.5kgf HB5/:25、62.5、125、187.5kgf HB10/:100、187.5kgf HBT2.5/:62.5、187.5kgf HBT5/:187.5kgf |

| Measuring range of Rockwell | A, B, C, D, E, F, G, H, K, L, M, P, R, S, V 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W 15X, 30X, 45X, 15Y, 30Y, 45Y |

| Measuring range of Vickers | HV3、HV5、HV10、HV20、HV30、HV50、HV100kgf HVT50、HVT100kgf |

| Measuring system | Through optical objective lens and CCD camera to collect indentation image and measure in the interface of LCD. Resolution: Length reading:0.1 micron menter Depth reading:0.2 micron metere |

| Objective magnifications | 5x、10x 、20X |

| Camera | 1280*1080 pixel, 1/2’’ |

| Data display | By computer to display data |

| Measurement | Automatic loading, dwell and unloading |

| Indenters | Rockwell diamond indenter: 120° Rockwell ball indenter: 1/16“, 1/8“, 1/4“, 1/2“ Vickers diamond indenter: 136° Brinell ball indenter: 1mm, 2.5mm, 5mm, 10mm Part of them are optional accessories. |

| Dwell time | 1 - 99 s |

| Illumination system | LED lamp, annular lamp |

| Standard conforms to | GB/T230、GB/T231、GB/T4340、JJG144-1999、GB/T18449、ISO 6508、 ASTM E 10、 ASTM E92、 ASTM E18、 ASTM E384、 ASTM E103 |

| Specimen specifications |

Max. height of specimen: 300mm Max. width of specimen:165mm Cylinder specimen:min. diameter of outer surface is 3mm; |

| Dimensions | 290mm x 520mm x 900mm (L x W x H) |

| Weight | 76kg |

| Power supply | 220V AC, 50Hz |

Standard Delivery:

| Item | Quantity | Item | Quantity |

| Main unit | 1 unit | Brand computer |

1 unit |

| Vickers indenter | 1pc |

Brinell indenters Dia. 1.0、2.5、5mm,10mm harden alloy ball |

Each 1pc |

| Rockwell diamond indenter | 1pc | Rockwell ball indenters: 1/16“, 1/8“, 1/4“, 1/2 | Each 1pc |

| Camera | 1pc | Inner & outer lamps | Each 1set |

| Hardness test blocks | 5pcS | Large, middle and V-shape test tables | Each 1pc |

| Power cord | 1pc | Sliding test table | 1pc |

| Objective lens 5x ,10x, 20X | Each 1pc |

Instruction manual |

1pc |